Dining room servery (recycled Eucalyptus)

Dining room servery-the drawer sides and back are constructed from recycled hoop pine. Dovetail joinery is used in most of my work. In my view, dovetails are a sign of fine craftmenship, although in reality I don't always make my own aspirational grade.

I often design a furniture piece on paper before committing it to wood. It is a useful way of ensuring that the design is balanced in terms of its dimensions, length, breadth and height. Having said that, it is rare that I don't change somehting, or many things on the way through the process. I am not sure that my tech drawing teacher from Chinchilla State High would mark my plans highly but they do the job.

This side-board was built during my oriental phase and before one's music was streamed via Spotify, hence space was provided for a stereo and for the storage of tapes and CDs. The above 2 pieces are the only ones that I have constructed from Brigalow .

I have only ever constructed one staircase. (recycled Eucalyptus) Bespoke, one-off furniture is my preferred style, rarely do I make more than one of anything, This is probably why chairs do not appear in my repertoire. It is also why my furniture takes time to make.

Dining table (recycled hoop pine, likely milled >100 years ago.

Student desk. This is one of 3 made for my kids. One now resides in Perth WA and the other 2 in Toowoomba (recycled hoop pine)

Mirror (new Australian Red Cedar)

Entertainment cabinet (new southern Silky Oak)

Dining Table to seat 10 (recycled eucalyptus, likely Iron Bark)

I recently tried my hand at carving using a rotary cutter attached to a small electric angle grinder. The Ash timber came from the garden.

I wanted to join my interests in photography and wood working and create a piece of furniture that reflected both. This case displays cameras that my family have owned over the past 70 years. The outer frame is crafted from Eucalyptus and the box frame from southern Silky Oak.

The grated roof removed to show the glass ceiling of the box

Dresser (recycled Hoop Pine).

Squatters Chairs (new Silky Oak).

Table with embedded marble chess board and drawer for storage of the pieces (new Queensland Maple)

Side Board (recycled Hoop Pine).

Jewellers Drawer Set. This was a restoration project (Australian Red Cedar).

Square Iron Bark posts were rescued from an old dairy which was to be bulldozed to make way for a housing development on the outskirts of Toowoomba. The building was at least 100 years old and the timber gnarly and with lots of character, it was also incredibly heavy,

....and beautiful once the surface timber layer had been removed.

Iron Bark is generally red in colour, the darker stripes are a result of surface cracking over the decades and the incursion of water and dirt. The 3 boards were joined but with a surface gap between which was in-laid with a square brass strip. The curve of the end grain can be seen on the table end.

The top of the table was gouged out on the bottom side to provide a hidden space with a drop down drawer created to hold electronic devices including a DVD. player The drawer is held shut by magnetic catches. Tongue and groove boards were created to form the base of the drawer.

Entry table with curved drawer front (recycled Eucalyptus).

The table top was constructed of Oregon Pine (Pseudotsuga menziesii), also called Douglas Fir, a native pine of America. Luckily it is quite a light (but strong) timber which made construction and movement of the table easier. My first job was to reduce the table to a size more appropriate to dining. At 2.75 m long and 1.2 m wide, it was still a large table. Reducing the size also provided a source of spare parts to replace damaged and broken or missing bits, particularly the rotating dowells.

Changing the dimensions of the table meant that the corner dovetails had to be replaced. They were an interesting design, not glued, but pinned. This resulted in movement in the joint which I suspect was intentional, allowing the table to sit squarely on all four legs no matter the condition of the wool shed floor.

Cypress Pine (Callitris glaucophylla) was used for the legs (100 x 100 mm square). They were in pretty poor shape. Cyprus Pine is a native of eastern Australia with its most noteable attributes being its termite resistence and distinctive smell. It is commonly used for framing and the exterior cladding, particularly in areas where termites are an issue.

Decadal buildup of grease and dirt on the oregon frame of the table. The axles of the dowells, which made up the table top fitted into the holes shown along each side of the table. When in operation as a classing table, the fleece would have moved easily across the table supported by the rotationg dowells.

The finished product, before the glass top was placed.

The Nobby blacksmith preparing the forge to create the corner brackets required to stabilise the table. These were made from steel sourced from an old tyned farming implement found in the smithy's yard.

111

111

111

The finished product, ready for 10 diners.

Using the surplus dowells and frame from the wool table, I was able to produce an interesting entry table .

As a farm kid, this chest lay in the barn, loved only by the rats and mice that frequented the area. Many moons later, I cleaned it up to find that it was constructed of Oregon Pine with a beautiful pattina hiding under the grime. The missing lid was replaced, an internal drawer built and a new lock installed, It is thought that the chest belonged to my grandfather, Robert Gill Dalgliesh (1876-1935) or his cabinet-maker brother John (1877-1936) both of whom emigrated from Scotland in 1911 and settled in southern Queensland.

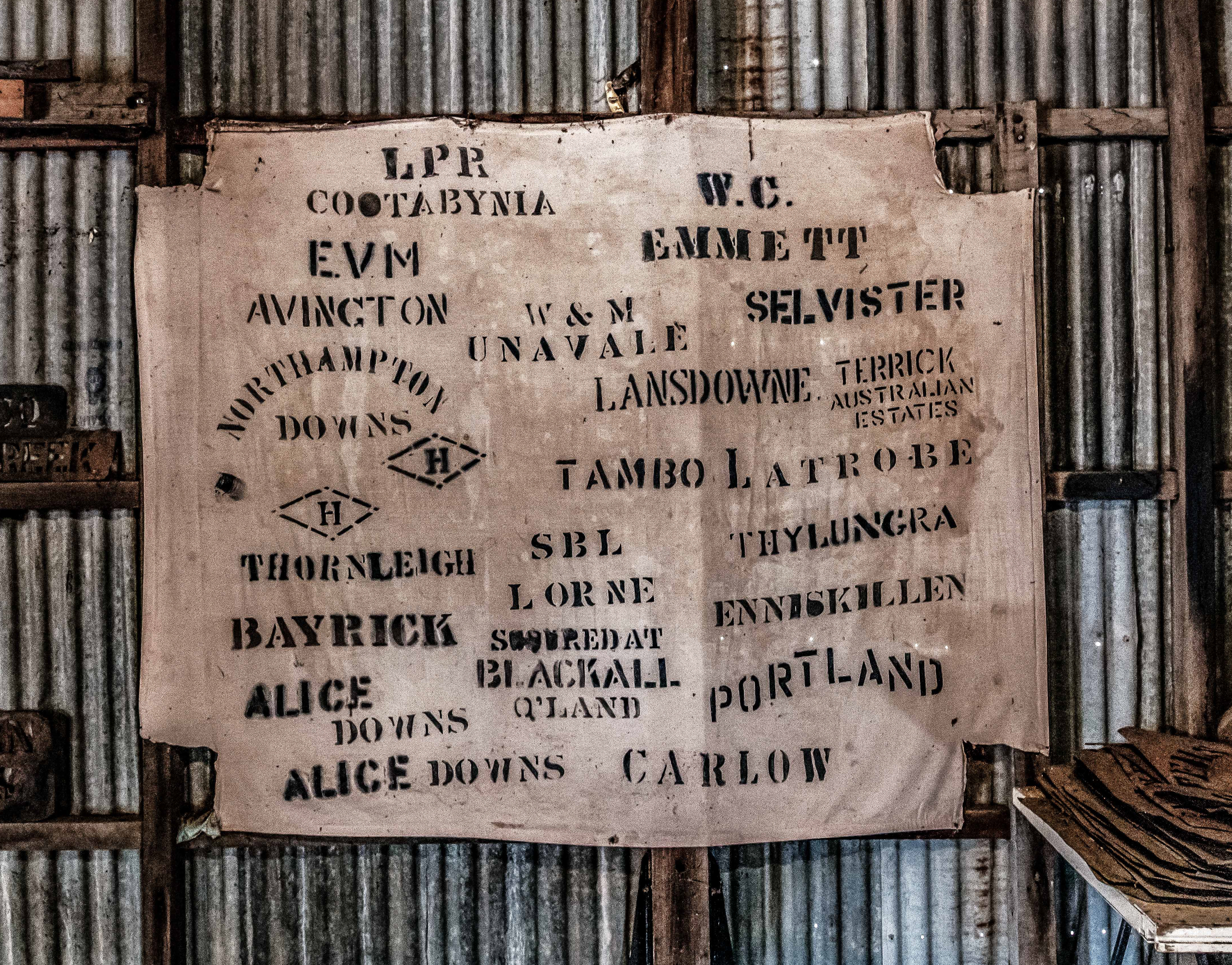

Over the years, I have collected a range of wood working tools, particularly, wooden planes. The display case was built using timber from an historic shearing shed located at Back Plains, south of Toowoomba. The cabinet is made from the hardwood frames of the sheep holding pens and the back, from the pens hoop pine cladding. The writing on the back wall shows the tallies of sheep shorn, for a number of shearers working in the shed in the very early 1900s.

Dining table made from recycled Eucalyptus, the timber was sourced from a demolition in Goondiwindi. This is one of six tables of similar dimension, but all very different, made between 2017 and 2021.

An hardwood bearer from a Toowoomba house renovation (recycled Eucalyptus) was used to make the following bed head and side tables.

King size bed head (recycled Eucalyptus).

Bedside table and bed head

The dining table is one of a number of bespoke pieces made for Mr Cooper. The brief was to make a table of a particular size to fit within a relatively small dining area, to use hardwood and to incorporate, already owned hand made glass tiles into the surface of the table. I was lucky enough to be offered Iron Bark facia boards from the demolition of a house built in the 1950s on the Toowoomba Range. There was something like 60 metres of 300 x 25 mm boards being used as facias. The table is stabilised by a squaare solid bar, threaded at each end and bolted to the end frames.

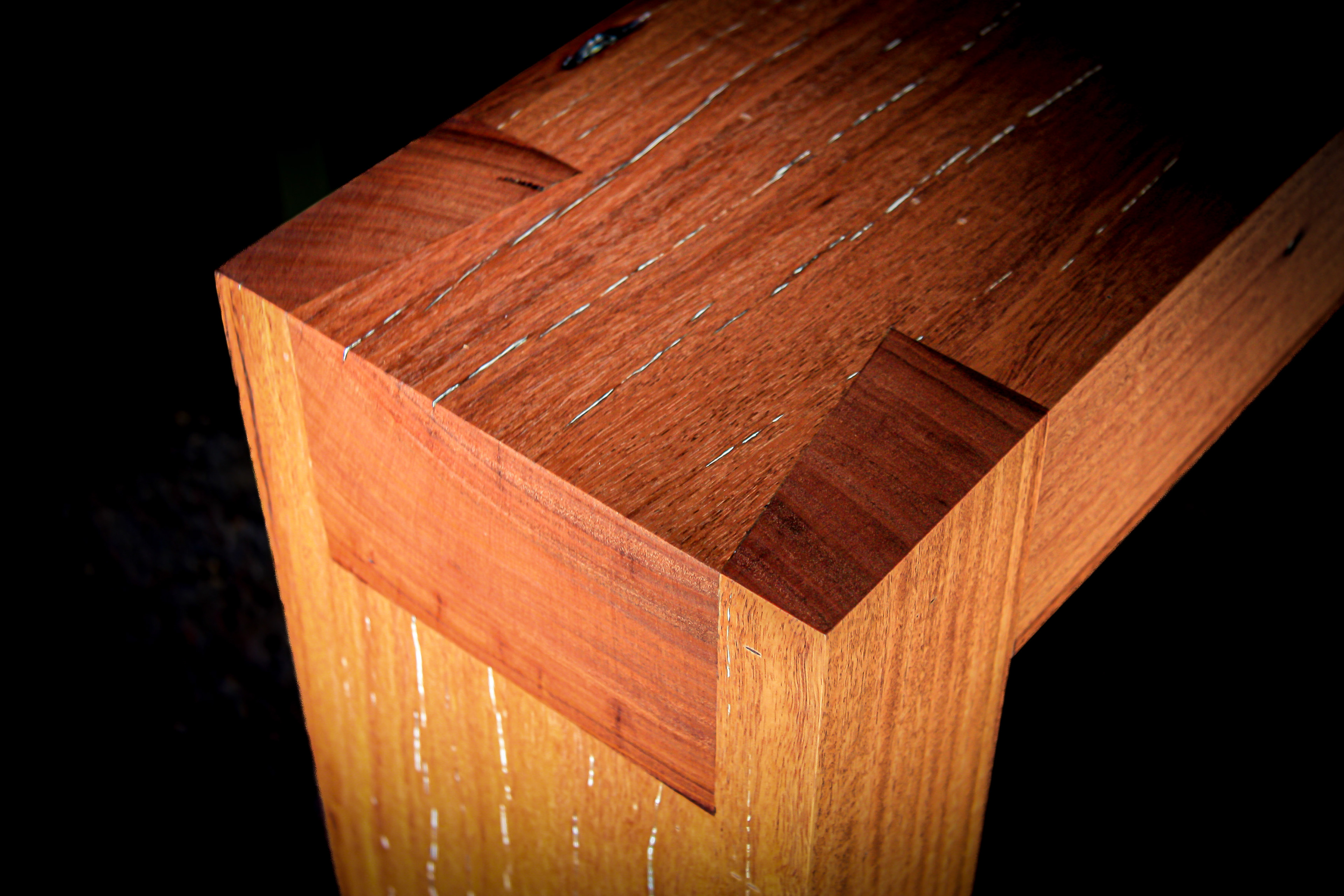

I was asked to build a feature table for a lounge room. The size of the timber bearer seemed ideal. The table features large, single dovetail joinery .

A happy customer.

A set of shelves were built to accommodate books and bits and pieces and inserted into the space below the kitchen servery, but looking out into the lounge room. A neat way of utilising a space that was otherwise wasted (new Queeensland Maple).

The original condition of the doors including the wrought iron hinges and closing spring.

Three doors were utilised to form the 2500 x 950 mm table top. An additional door was used to replace damaged boards leaving 2 doors still awaiting another burst of inspiration (coffee table maybe?)

The numbers displayed on the doors were used to identify each of three shearing points on the shearing board. An individual shearer would man each point and select his sheep for shearing from his pen. He would be paid based on the number of sheep shorn during the day.

It is always an exciting moment when the piece of furniture has been lightly sanded and the beauty of the timber starts to emerge as the oil is applied.

Ready for Christmas lunch 2022

The scratches on the table top are a mystery although it almost looks like they may have been made by the shearing hand piece.

Hand forged steel table bracing and recycled eucalyptus (species unknown) timber legs and undercarriage

Solid steel foot rest and recycled timber bracing